While you may ignore economics, it won’t ignore you.

—Don Reinertsen, Principles of Product Development Flow

Principle #1 – Take an economic view

Realizing the goal of Lean—which means achieving the shortest sustainable lead time with the best quality and value—requires understanding the economics of a mission. Without that, even a technically competent system may cost too much to develop, take too long to deliver, or incur exorbitant manufacturing or operating costs.

That’s why the entire chain of leadership, management, and knowledge workers must understand the economic impact of the choices they’re making. Traditionally, the budgets of their activities were known only to the decision-makers who understood the business, marketplace, and customer finances. This meant that a worker’s everyday decisions were made without this information or escalated to those who had it. That resulted in delays, inefficiencies and a lack of empowerment by the people closest to the work.

Therefore, SAFe’s first Lean-Agile Principle is to take an economic view. It is Principle #1 for a reason. Economics should inform and drive decisions at all levels, from Portfolio to Agile Teams. While many factors can contribute to failed solutions, poor economics is one of the most common.

This article describes the two practices essential to achieving optimum economic outcomes via Lean-Agile methods:

- Deliver early and often

- Apply an economic framework

Each is outlined in the sections below. And although it’s essential for every knowledge worker to understand them, many of these principles are already embedded directly into various SAFe practices.

Deliver Early and Often

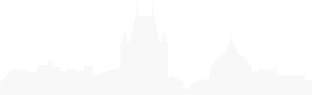

Enterprises decide to embrace Lean-Agile development either because their existing processes aren’t producing the results they need, or because they anticipate that they won’t in the future. By choosing a Lean-Agile path, they’re embracing a model based on incremental development and early and continuous value delivery, as Figure 1 illustrates.

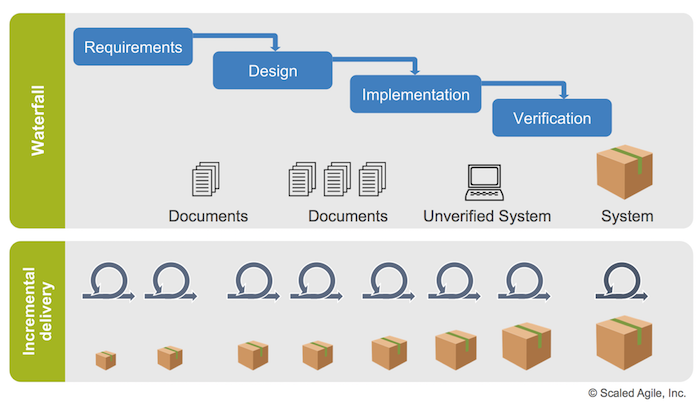

The ability to deliver early and often has a direct economic benefit, as illustrated in Figure 2.

This figure shows how Lean-Agile methods deliver value to the customer much earlier in the process. What’s more, this value accumulates over time: The earlier and longer the customer has it, the more value they receive. Conversely, with the waterfall model, value can’t even begin to accumulate until the end of the development cycle.

This difference is a material economic benefit of SAFe. In addition, the figure above doesn’t even account for the advantage of far faster feedback, or the probability that the waterfall delivery would not occur on time. And there is a third factor, as shown in Figure 3.

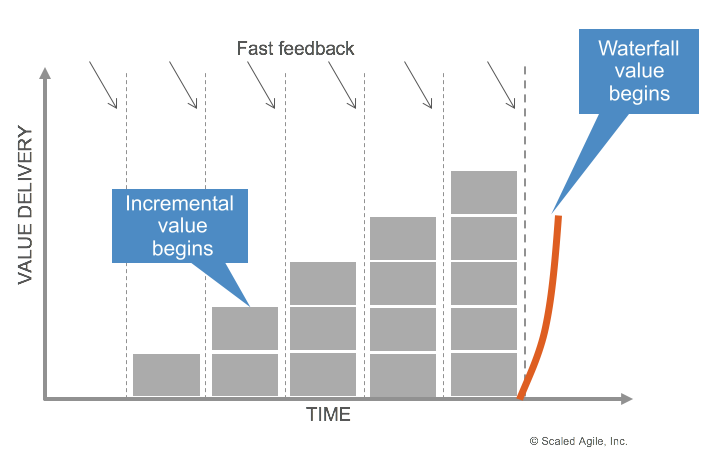

Figure 3 illustrates another key differentiator. As long as the quality is high enough, products and services delivered to market early are typically more valuable. After all, if they arrive ahead of the competition, they are worth a premium as they aren’t available from anyone else. Over time, features become commoditized. Cost, not value differentiation, then rules the day. This means that even a Minimum Viable Product (MVP) can be worth more to an early buyer than a more full-featured product delivered later.

The net effect is that cumulative gross margins are higher. For government agencies and non-profits where gross margin is not a factor, the same concept results in more effective value delivery for the funds provided by taxpayers and donors. This is the basic premise of Lean-Agile development, one that’s firmly entrenched in the Lean-Agile Mindset.

Apply a Comprehensive Economic Framework

But as important as it is, delivering early and often isn’t the entire picture. Additionally, every SAFe portfolio requires an Economic Framework—a set of decision guidelines that align everyone with the financial objectives of a Portfolio and inform the continuous decision-making process. After all, teams and Agile Release Trains (ARTs) make small and large decisions every day. Their choices can influence economic outcomes positively or negatively. Without guidance, self-organizing teams will just make their ‘best guess.’ Although this can result in decentralized decisions, they may not be aligned with the core economics of the system, creating the potential for technical debt, rework, waste and a lack of fitness for use.

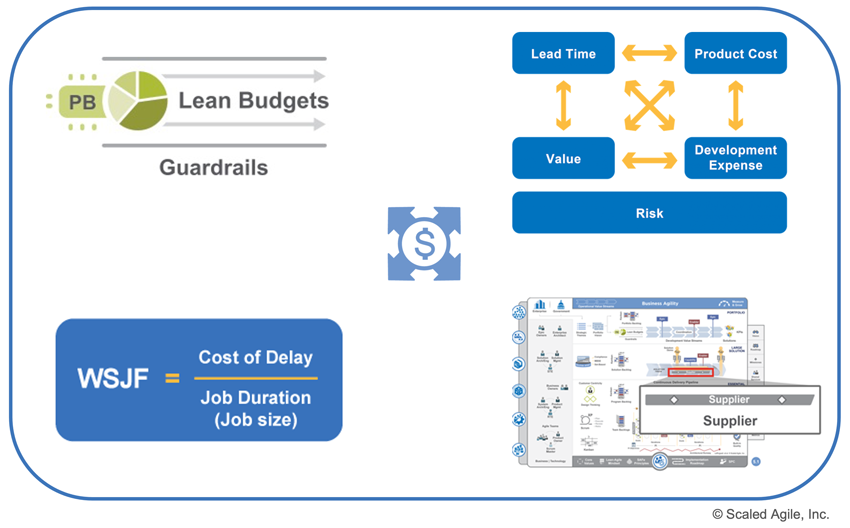

As illustrated in Figure 4, SAFe’s economic framework contains four primary elements:

- Operating within lean budgets and guardrails

- Understanding solution economic trade-offs

- Leveraging suppliers

- Sequencing jobs for the maximum benefit

Operate Within Lean Budgets and Guardrails

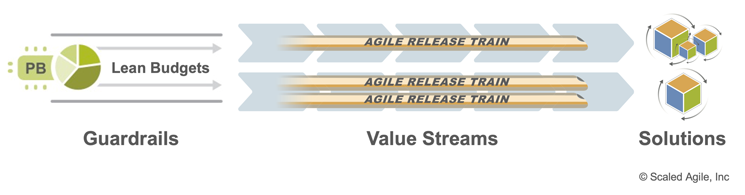

As described in the Lean Budgets article, one of the most significant transitions for the Lean-Agile enterprise is to move from project-based, cost-center accounting to a more streamlined budget process. In the new model, the funding is allocated to long-lived portfolio value streams. To support these higher-level budgets, budget guardrails (Figure 5) inform the oversight and governance that guide ongoing spending decisions.

As described in the Guardrails article, SAFe suggests four specific guardrails:

- Guide investments by horizon

- Optimize value and solution integrity with capacity allocation

- Approve significant initiatives

- Continuous business owner engagement

Every solution inherits the guardrails of the corresponding value stream as defined by Lean Portfolio Management (LPM). Budgets and guardrails define the boundaries within which Solution Train and ART leaders make decisions on the definition, scope, and sequence of epics, capabilities, and features. As context changes, these guidelines are updated periodically.

Understand Solution Economic Trade-Offs

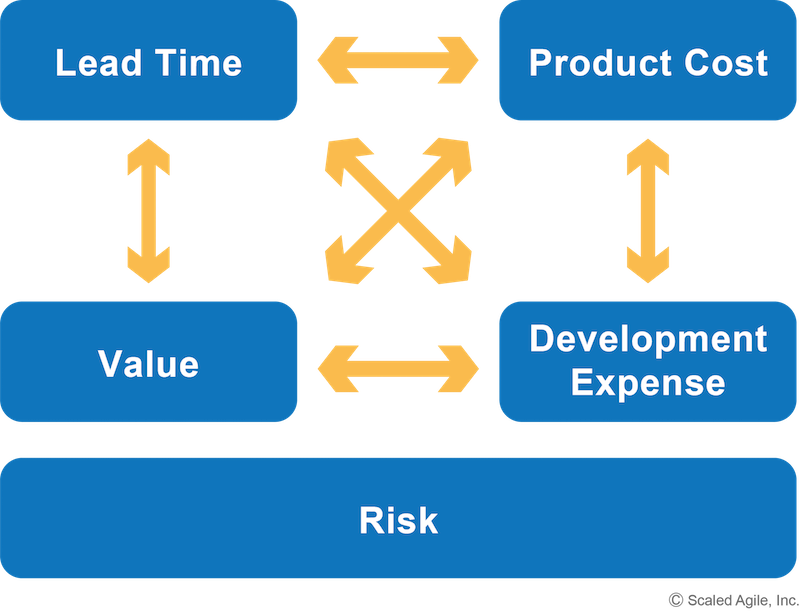

Within the degrees of freedom that lean budgets and guardrails provide, there are still many alternatives and tradeoffs for what to build and how and when to build it. Reinertsen [1] identifies five considerations that affect these decisions:

- Development expense – the cost of labor and materials required to implement a capability

- Lead time – the time needed to implement the capability (described as ‘Cycle time’ in Reinertsen’s work)

- Product cost – the manufacturing cost (of goods sold) and/or deployment and operational costs

- Value – the economic worth of the capability to the business and the customer

- Risk – the uncertainty of the solution’s technical or business success

The arrows in the diagram in Figure 6 are the key to the model. They illustrate that changing any variable can have an impact on one or more of the others. For example, a company can add developers to an initiative that’s behind schedule, but that will also increase the development cost. And if development costs drive the product costs up, economical pricing may become unrealistic. Understanding how each variable influences the others is vital to making the proper trade-offs.

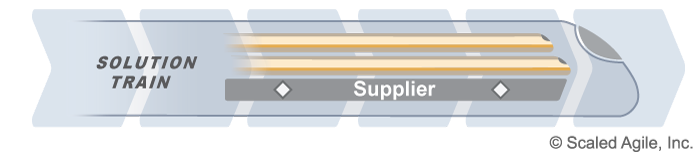

Leverage Suppliers

“End the practice of awarding business on the basis of price tag. Instead, minimize total cost. Move toward a single supplier for any one item, on a long-term relationship of loyalty and trust.”

— W. Edwards Deming

To augment their internal workforce, or to provide components within the system-of-systems, most organizations building large solutions depend on external suppliers. They do this for two reasons:

- Insufficient workforce capacity. Outsourcing can provide a cost-efficient way to add personnel, especially if the need is temporary or when demand is highly variable.

- Availability of specialty components personnel or skills sets. A supplier may provide specific hardware, software, or skills needed for the solution. It may be significantly more economical to buy the component and integrate than it is to build it.

Since the money directed to external suppliers can represent a significant percentage of the overall cost of the solution, decisions regarding suppliers are a critical component of the economic framework.

An essential part of supplier economics is the relationship between the buyer and the supplier:

- Some relationships are transactional. In a transactional relationship, such as purchasing off-the-shelf parts or components from a third party or routine staff augmentation, competitive pricing can create favorable economics.

- Other relationships are true partnerships, persistent and long-lived. Often, the buyer and supplier are co-developing the solution. In this instance, economic considerations are clearly driven by longer-term considerations. These may include residual licensing, implicit knowledge, ownership of intellectual property, or other considerations that recognize the dependence on the specialty knowledge the supplier brings to the table.

In either case, as Deming notes the most favorable economics emerge from longer-term considerations, mutual trust, and relationships where the supplier and buyer each have favorable economics (for example, see Agile Contracts for more detail).

In yet other cases, the best economics can be achieved through mergers and acquisitions of companies that have long-term strategic value to the solution and the competitive landscape of the market.

For further guidance on how to incorporate suppliers into solution development read the Suppliers article.

Sequence Jobs for Maximum Benefit

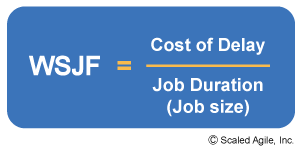

To increase the effectiveness of the solution, every significant program has a host of new backlog features and capabilities, just waiting to be implemented. However, SAFe is a flow-based system, in which job-sequencing optimizes economics versus theoretical job return on investment (or worse, first-come, first-served, loudest voice, or other historical patterns). Program and solution Kanban systems and the program and solution backlogs enable this. To minimize the cost of delay (COD), jobs are pulled into implementation based on Weighted Shortest Job First (WSJF). WSJF prioritizes the backlog to ensure the highest value is delivered in the shortest lead time.

Practices Provide the Form. People Make the Decisions

This article described some mechanisms for economic decision-making, the foundation for effective management based on economics. SAFe also defines the roles and responsibilities of people in the decision-making chain. However, those decisions don’t make themselves. Lean-Agile Leaders with the relevant context, knowledge, and authority lead the process. Of course, they don’t act alone. They empower practitioners and work with their larger stakeholder community to determine the best path. The concepts of the economic framework ensure that responsible decision-making happens throughout the development organization, bringing all the economic benefits of Lean-Agile development to the entire enterprise.

Learn More

[1] Reinertsen, Donald G. The Principles of Product Development Flow: Second Generation Lean Product Development. Celeritas Publishing, 2009.Last update: 10 February 2021